Ensuring Safety and Precision in Pipe Welding Inspection

In the world of pipeline welding inspection, making certain security and precision are critical objectives that demand meticulous attention. The integrity of pipelines pivots on the high quality of welds, making the inspection process a vital element of upkeep and construction.

Significance of Pipeline Welding Evaluation

Pipeline welding assessment is vital for guaranteeing the integrity and safety and security of the facilities - Pipeline Welding Inspection. Welded pipelines are an important part of various markets, including oil and gas, water transport, and chemical processing. The high quality of welds directly influences the structural security and long life of the pipelines. With careful evaluation, possible flaws, such as splits, incomplete penetration, or imbalances, can be detected and remedied before they bring about tragic failings.

Appropriate evaluation techniques, such as visual testing, radiographic screening, ultrasonic screening, and magnetic fragment testing, are used to analyze the top quality of welds. These approaches help ensure that welds fulfill industry standards and regulative demands. By identifying and attending to imperfections early in the welding process, the risk of leaks, tears, and ecological contamination is dramatically reduced.

Moreover, pipeline welding assessment plays an essential role in keeping conformity with security requirements and regulations. Regular assessments not only boost the structural integrity of pipes yet likewise add to the total security of procedures and personnel operating in the vicinity. Fundamentally, buying detailed pipeline welding inspection is an aggressive step to avoid pricey repairs, alleviate threats, and maintain the integrity of critical infrastructure.

Advanced Evaluation Technologies

Using innovative modern technologies in assessment enhances the precision and efficiency of evaluating weld high quality in pipes. Advanced assessment innovations play an essential role in ensuring the stability and safety and security of pipeline systems. Among one of the most noticeable innovations in pipe welding evaluation is making use of automated ultrasonic testing (AUT) AUT enables a much more extensive and accurate examination of welds by making use of robotic systems to execute examinations with high accuracy, lowering the threat of human error.

In addition, the implementation of phased array ultrasonic screening (PAUT) has actually reinvented the examination procedure by supplying comprehensive imaging of welds in real-time. PAUT uses better issue discovery capacities and enables for quick data analysis, allowing inspectors to make informed choices without delay - Pipeline Welding Inspection. Furthermore, electronic radiography (DR) has ended up being significantly preferred in pipe welding inspection due to its ability to produce top quality images that boost flaw presence while decreasing radiation exposure

Incorporating these advanced assessment technologies not only boosts the quality of weld evaluations but also boosts total security criteria in pipeline building and upkeep.

Function of Educated Inspection Professionals

The combination of advanced evaluation innovations in pipeline welding examination underscores the vital relevance of qualified assessment experts in guaranteeing the accuracy and integrity of analyses. Trained assessment professionals play a crucial duty in overseeing the application of these innovations, translating the information acquired, and making informed choices based upon their know-how.

These experts are equipped with the required understanding and abilities to conduct detailed assessments, determine prospective issues or abnormalities in welds, and ensure compliance with sector requirements and guidelines. Their capacity to examine data, identify patterns, and troubleshoot concerns is crucial in preserving the stability and safety of the pipeline infrastructure.

Furthermore, experienced inspection experts offer as an important web link in between technology and practical application. By leveraging their experience and training, they can supply important insights, suggestions, and services to enhance the welding procedure and mitigate risks properly.

Precaution in Welding Evaluation

Reliable implementation of security actions in welding inspection is paramount to guaranteeing the protection of employees and the honesty of the facilities. Welding assessment tasks include different hazards such as direct exposure to fumes, electrical shock, and fire threats. To reduce these risks, adherence to safety procedures is important. Workers associated with welding assessment need to put on appropriate individual safety devices (PPE) such as headgears, gloves, shatterproof glass, and fireproof clothes to reduce the threat of injuries. In addition, guaranteeing proper ventilation in the welding area helps in lowering exposure to unsafe fumes and gases produced during the welding procedure.

Routine safety training sessions must be conducted to inform inspection specialists on the latest safety and security treatments and procedures. By prioritizing safety and security procedures in welding inspection, companies can develop a safe and secure her latest blog working environment and support the top quality and integrity of pipeline facilities.

Ensuring Precision in Evaluation Practices

With a concentrate on careful focus to detail, achieving accuracy in inspection techniques is crucial for making certain the quality and integrity of pipe welding. Precision in evaluation techniques includes adhering to strict criteria and guidelines to properly assess the welds for any issues or flaws. Using advanced examination innovations such as ultrasonic testing, radiographic testing, and aesthetic assessment techniques is critical in recognizing even the tiniest imperfections that can endanger the safety and security and capability of the pipe.

Making sure accuracy in examination techniques likewise calls for trained and certified inspectors that have a deep understanding of welding processes, products, and market policies. These assessors must possess the ability to translate evaluation outcomes properly and make educated choices regarding the approval or rejection of welds based upon predefined standards.

Routine calibration and maintenance of evaluation tools are extremely important to assuring the dependability and accuracy of evaluation outcomes. By upholding high requirements of accuracy in examination techniques, stakeholders can believe in the architectural integrity and efficiency of pipeline welds, ultimately contributing to the general safety and effectiveness of the pipeline system.

Final Thought

To conclude, the importance of pipeline welding inspection can not be overstated. Advanced assessment innovations and skilled examination specialists play an essential duty read this in making sure safety and security and precision in welding methods. By adhering to stringent precaution and preserving precision in assessment treatments, the go to this web-site integrity of pipelines can be maintained, protecting versus possible hazards and making certain the proceeded performance of the system.

Using innovative examination modern technologies such as ultrasonic testing, radiographic testing, and visual assessment techniques is critical in recognizing also the tiniest flaws that can endanger the security and capability of the pipeline.

Advanced assessment modern technologies and trained examination specialists play an important duty in ensuring security and accuracy in welding practices.

Alana "Honey Boo Boo" Thompson Then & Now!

Alana "Honey Boo Boo" Thompson Then & Now! Tatyana Ali Then & Now!

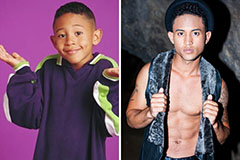

Tatyana Ali Then & Now! Tahj Mowry Then & Now!

Tahj Mowry Then & Now! Macaulay Culkin Then & Now!

Macaulay Culkin Then & Now! Samantha Fox Then & Now!

Samantha Fox Then & Now!